Achieving the goal of the Paris Agreement with CCS

The Paris Agreement is a legally binding international treaty on climate change, adopted at the UN Climate Change Conference (COP21) in Paris, France in 2015 and entered into force the next year. Its overarching goal is to hold “the increase in the global average temperature to well below 2°C above pre-industrial levels” and pursue efforts “to limit the temperature increase to 1.5°C above pre-industrial levels.”

Most efforts to achieve this goal include carbon capture and storage which could account for nine percent of the CO2 reduction or 2.4 gigatonnes per year in 2040. With the carbon capture and storage project pipeline growing by 48 to 111 million tons per annum in the first nine months of 2021, CO2 storage is on the threshold of becoming a realistic tool to mitigate climate change.

A complementary role for shipping

CCS is an established technology and capture hubs are being developed. But we will need more than 20 times the current capacity by 2030 to meet ambitious climate goals. About 10-20 large hubs must go on-stream every year if we are to succeed.

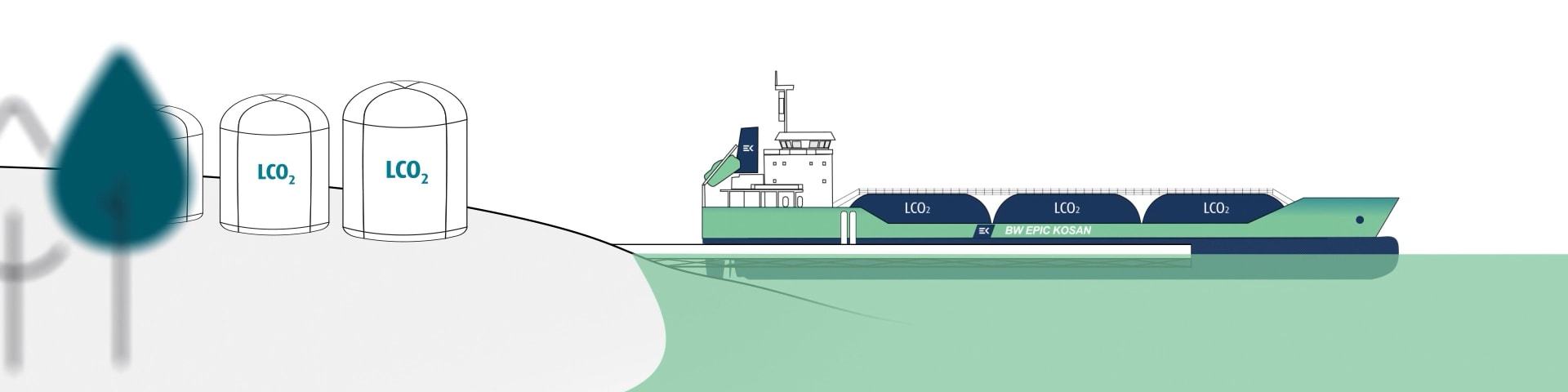

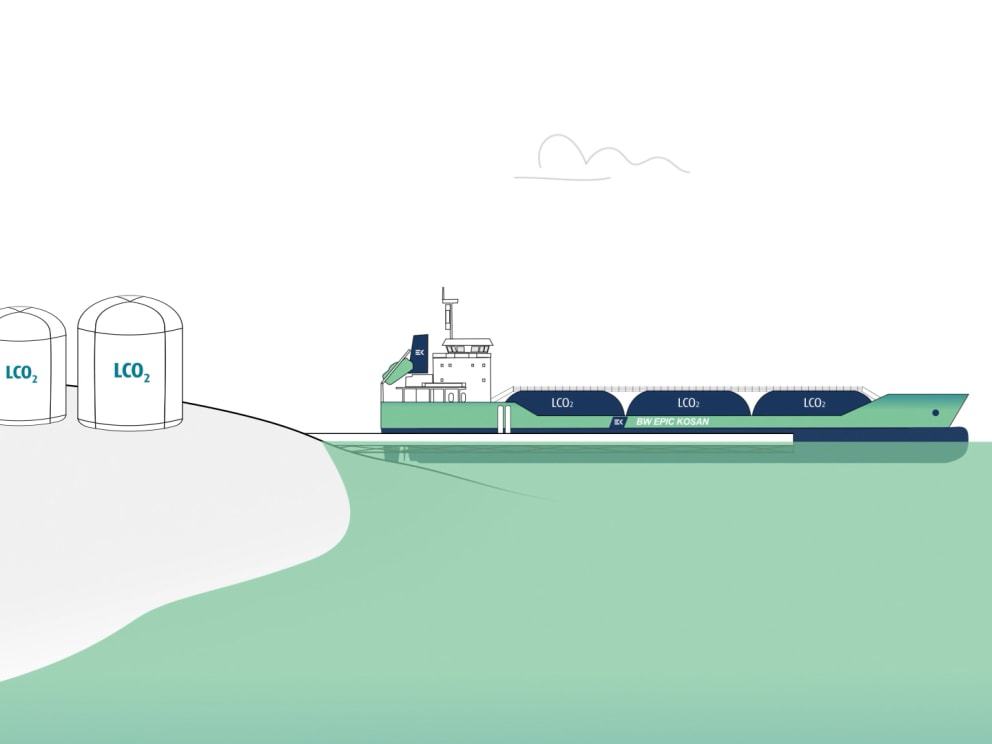

CO2 storage sites are often far away from producers. With a need to move an estimated 90 million tons of CO2 annually to storage sites by 2040, linking CO2 producers with storage facilities will be increasingly important. While the majority of CO2 will be transported by pipelines, this may not be possible or suitable for all locations and distances. This is where shipping can play a complementary role.

A Preferred Shipping Partner

BW Epic Kosan is the world’s largest seaborne transporter of intra-regional gases. In a typical year, we perform over 4,000 cargo operations and transport 5.5 million tons of gases and petrochemicals, calling at over 300 different ports world-wide. This translates to an average of five load operations every day.

Today we have a fleet of approximately 60 ships on the water trading all over the world. The commodities we carry are a mix of propane and butane (Liquefied Petroleum Gas or LPG) as well as petrochemicals. Typically, the LPG carried on our vessels is used for heating and cooking in developing economies, and the average duration for these voyages ranges from five to six days at sea. The pathway for us into the carriage of CO2 carbon is predicated on our knowledge, skills and expertise in the carriage of speciality gases that we already have.

Some of our specialised vessels can already be adapted to carry CO2 – these smaller vessels provide optimal flexibility and accessibility, and are oftentimes the “right size” for CO2 transportation, where one vessel can carry 10,000 tonnes of CO2, equivalent to 10 days of CO2 output from a large cement plant. We are also working with partners on much larger vessels where longer-haul shipping requirements are more likely.

In addition, we have the knowledge and experience to build new cargo-flexible, low-emissions vessels. From a timeline perspective, an existing vessel can be converted to be CO2-ready within a few months, and a dual-fuel newbuild will be ready within two to three years.

Leveraging on the BW Group

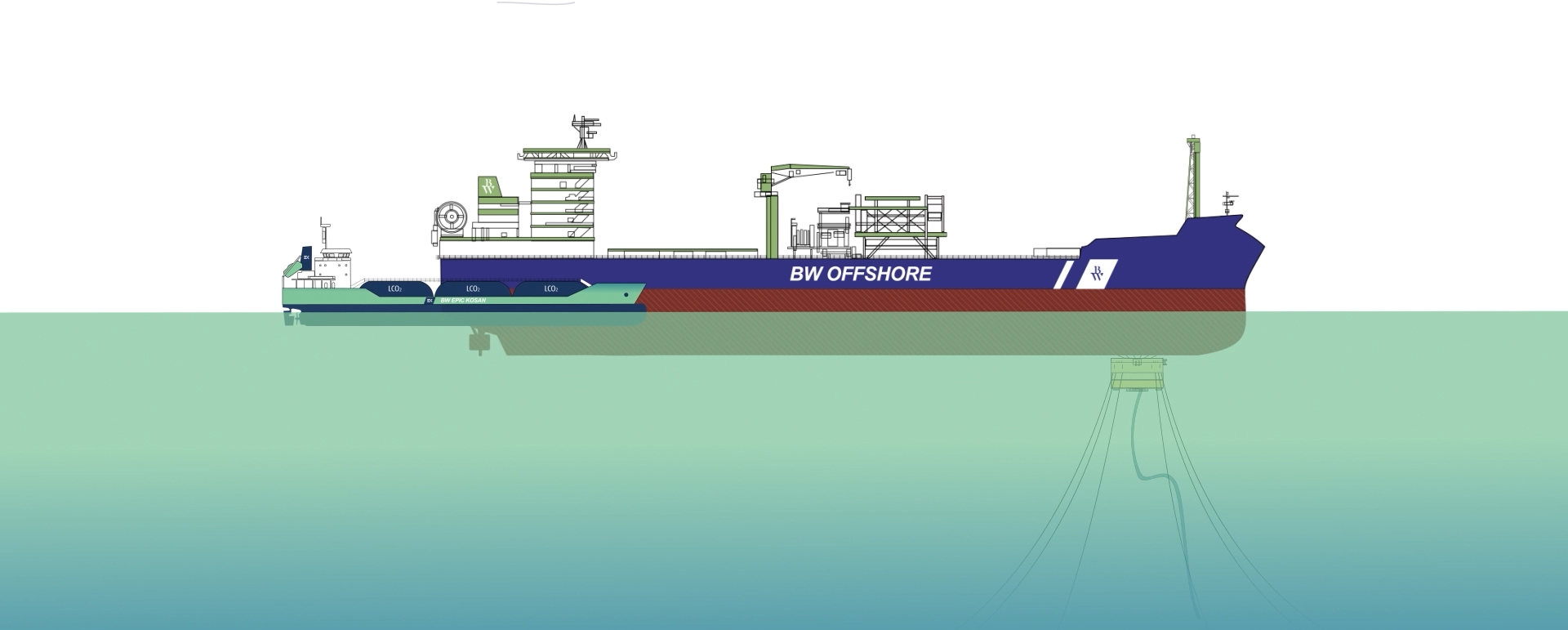

As part of the BW Group, we leverage over 90 years of collective experience in project execution; operation of vessels, floating gas infrastructure and offshore production systems, as well as management of oil & gas reservoirs. With our combination of shipping and offshore competencies, we offer customers safe and cost-efficient end-to-end carbon sequestration solutions, based on floating assets.

LCO2 vessels can offer significant advantages over pipelines, especially over long distances where pipelines are uneconomical. Right-sized vessels can be used to sail to storage facilities safely and cost-effectively. LCO2 vessels also offer more flexibility. They can onboard new capture projects quickly and add capacity with minimal investments in new infrastructure.

Our vessels can sail to floating injection terminals located offshore. These floating injection terminals are a flexible and cost-effective alternative to fixed infrastructure. They can be deployed and redeployed where there is no existing pipeline, which reduces capital expenditure and shortens lead time. They will also incorporate buffer storage to smooth out intermittent shipping flow and simplify reservoir management.

Carbon Capture & Storage (CCS) as One Way to Help Achieve the Goal of the Paris Agreement

Carbon capture and storage is a realistic solution that can be utilized by industries that need to urgently reduce their carbon footprint. Our long-standing heritage of transporting LPG, specialty gases and other petrochemicals is built on the highest safety and operating standards. We can simplify and de-risk our customers’ CO2 emissions management process, by supporting the transportation and storage of LCO2 as part of overall efforts to decarbonise. Watch our video for more information.